Comprehensive manufacturing solutions with in-house R&D, design, tooling, and production

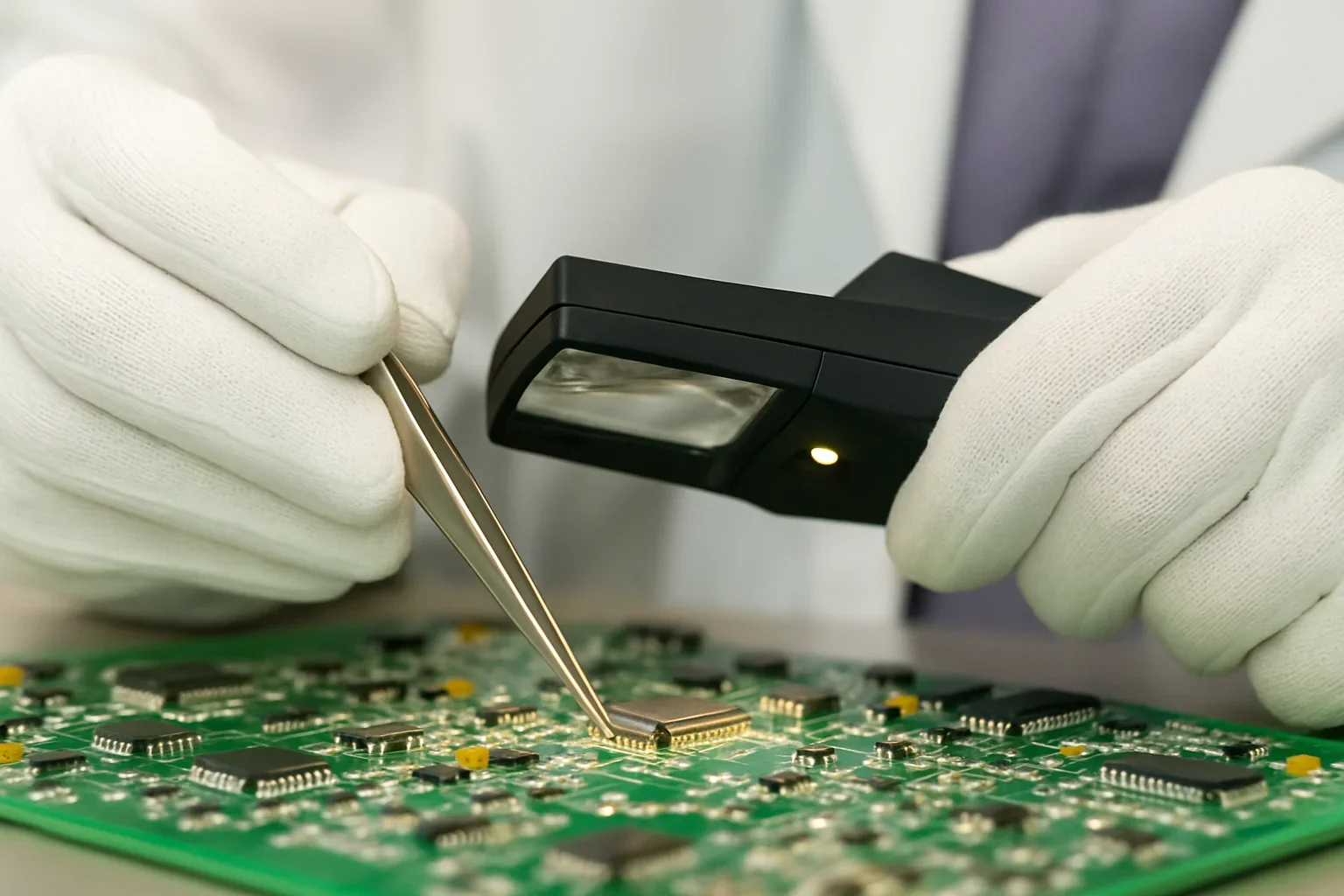

LIT Group offers comprehensive Electronics Manufacturing Services (EMS) in India, covering the full product lifecycle from initial design and prototyping to high-volume manufacturing and testing. As a specialized EMS company in India, our vertically integrated approach includes PCB layout, component sourcing, assembly, inspection, and final production. Our in-house design engineers work closely with clients to enhance manufacturability, reliability, and cost-effectiveness while maintaining strict quality standards.

Why Choose LIT Group for Electronics Manufacturing Services in India

Stringent quality control processes and industry certifications ensuring reliability.

Quick turnaround for prototypes and design iterations to accelerate time-to-market.

Expert analysis to improve manufacturability, performance, and cost-effectiveness.

Flexible manufacturing capabilities from low to high volume production runs.

Explore our comprehensive electronic manufacturing services

Our expert engineering team provides comprehensive PCB design services, from initial concept to final production. We specialize in multi-layer board designs with advanced signal integrity analysis to ensure optimal performance.

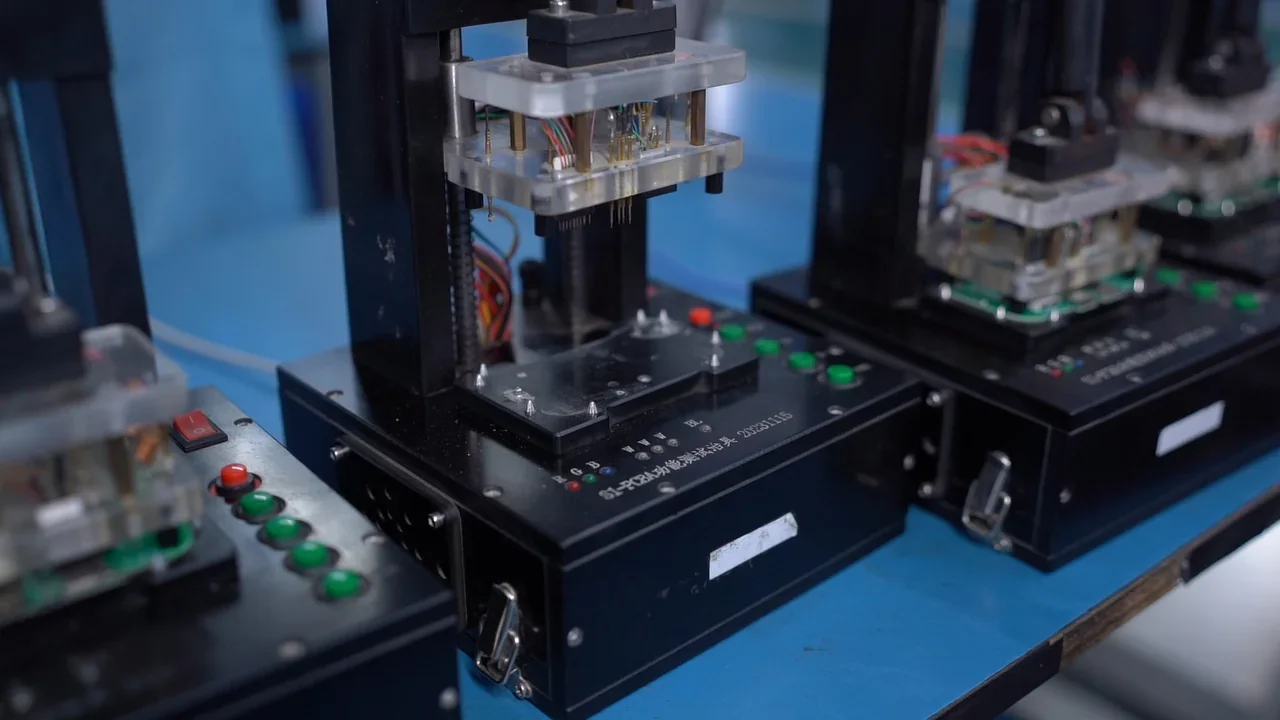

Our state-of-the-art SMT production lines deliver high-precision, high-volume assembly capabilities. We handle components of all sizes, from large ICs to micro-components with exceptional accuracy and consistency.

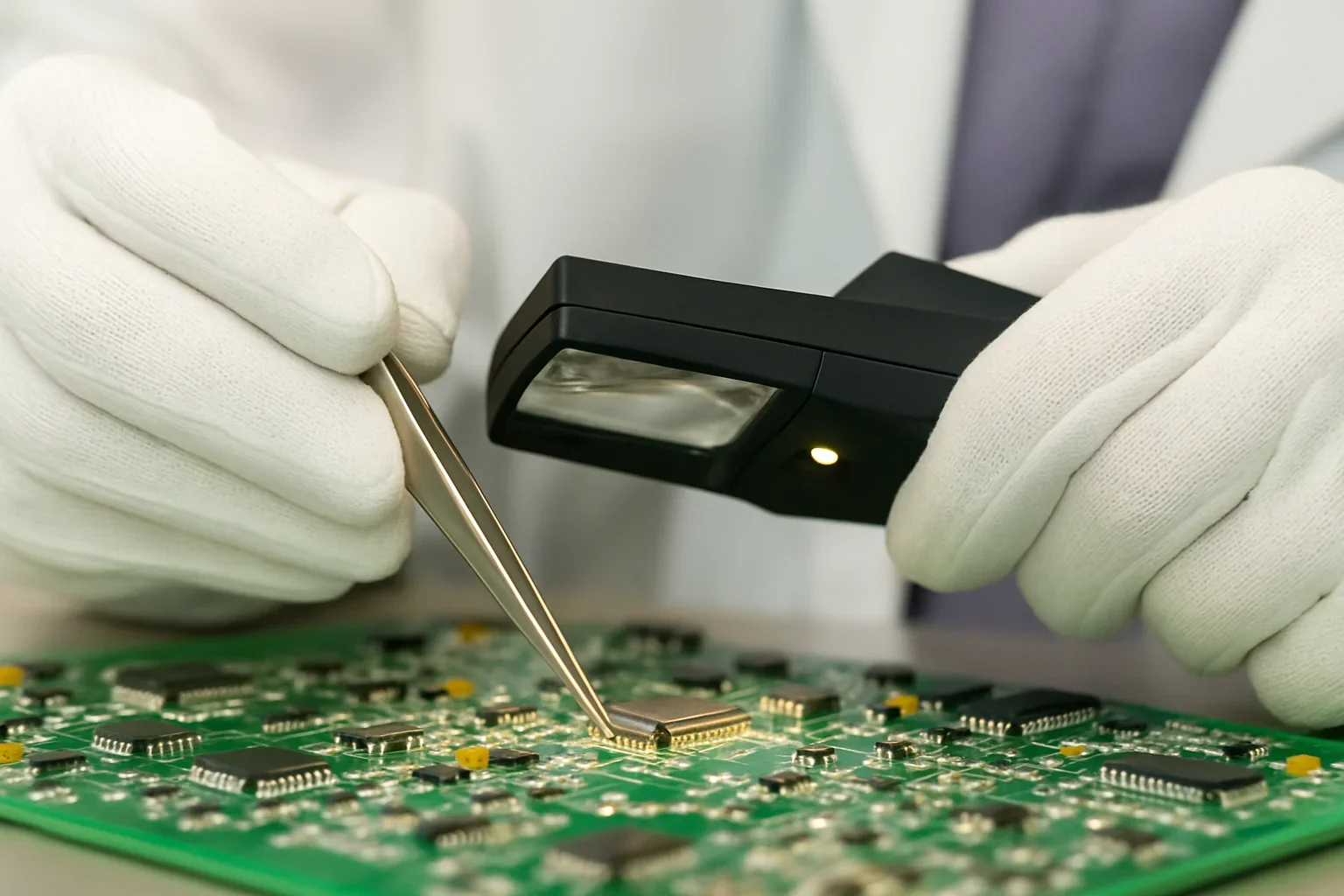

Our comprehensive testing protocols ensure every product meets the highest quality standards. From automated optical inspection to functional testing, we verify performance at every stage of manufacturing.

Our manufacturing facilities are equipped to handle high-volume production with consistent quality. We implement lean manufacturing principles and just-in-time delivery to optimize efficiency and reduce costs.

Our manufacturing expertise serves diverse industry sectors

Manufacturing solutions for remote controls, smart home devices, and personal electronics products.

Robust electronic assemblies for industrial control systems, automation, and monitoring devices.

Specialized electronics for heating, ventilation, and air conditioning control systems.

Precision manufacturing for medical diagnostic equipment and healthcare monitoring devices.

Contact us to discuss your specific requirements and explore how we can support your project

Get in Touch